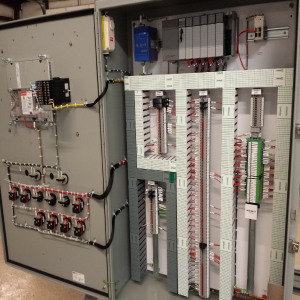

Our panel shop is located in Cypress just outside Houston, Texas. We have 2000 square feet dedicated to control panel projects.

Our team specializes in providing UL explosion-proof ( NEMA 7, ATEX, IEC Ex) and stainless steel UL Type 4x, NEMA 4X) panels for hazardous locations and corrosive environments.

Rig-Tech is

also capable of building per UL 508a (Category NITX), NNNY

hazardous-locations for UL Class I Division I &

II.

AC Drive | PLC Panels

| Remote I/O Panels | Operator Stations HMI Panels | AC Motors |

Junction Box/Marshalling Panels Transformers | Combination Starter

| DC Drives

CUSTOM CONTROL PANEL

PROJECTS

Rig-Tech can handle any custom panel project, and we offer engineering support from design concept to completion. Whatever your needs, we have the expertise, the resources, and the customer service to make your project a success.

Food & Beverage | Petrochemical | Oil & Gas | Industrial

Control Panel Services

Your Success. We are committed to your

success above all else. For each project, we establish an internal

team that meets throughout the life of your project to ensure your

requirements and expectations are met.

Added Value. Rig-Tech provides you with

added value in every stage of your project. We partner with

you in the design, build, test and certification of your control

panels and system.

Expertise. Our manufacturing process has

been continuously improved and refined since building our first

control panel. Our expertise is backed up with certifications – UL,

CE, and ATEX.

Quality. The quality procedures, processes and

personnel at Rig-Tech are unlike that of any company in the

industry. It’s the cornerstone of our culture.

control panels - control panel shop - plc panels - panel shop control panels - control panel shop - plc panels - panel shopcontrol panels - control panel shop - plc panels - panel shop

Testing Conitrol

Panels

All panels fabricated by Rig-Tech undergo a detailed, documented Panel Checkout Procedure developed specifically for each panel. To assure that your panel matches its specifications perfectly, we have a 65 point QA checklist and every control panel is hot tested before delivery. All PLC output points and hardwired circuits are hot verified. All circuits are checked for continuity and ground faults.

Panel Quality Assurance Checkouts include, but are not limited to:

Panel power-up and fusing testing

Wire continuity testing

I/O simulation

Operator Interface verification

Terminal torque testing

Nameplate and wire tagging verification

Other testing as required for complete functionality

100% testing

Instrument set up and

calibration

Device Simulation